Buy Direct from Manufacturers: Premium Import Activity Eyes & Custom Toy Accessories

For artists and designers crafting handmade dolls, plush toys, or collectible figures, the search for the perfect materials often feels like chasing shadows. You’ve imagined a character with soulful gaze and intricate details — but where do you find components that match your vision? Too often, creators settle for generic parts from local craft stores or overpriced resellers. What if you could bypass the middlemen entirely and access the source?

When Creativity Meets Origin: Lifting the Veil on Manufacturer Direct Supply

Lena, a Toronto-based doll artist, once spent months trying to replicate a vintage French doll’s wistful expression. Off-the-shelf eyes lacked depth; online suppliers offered inconsistent quality. Then she discovered direct sourcing from European manufacturers. No distributors, no markups—just authentic Czech glass eyes shipped straight to her studio. The difference was immediate: richer color gradients, lifelike translucency, and a durability that resisted yellowing over time.

This is the power of buying direct. By connecting creators with factories specializing in artisanal toy components, we eliminate layers of markup while ensuring superior consistency and craftsmanship. It’s not just about lower prices—it’s about reclaiming creative control.

The Global Journey of an Animated Gaze: From Italian Workshops to North American Craft Fairs

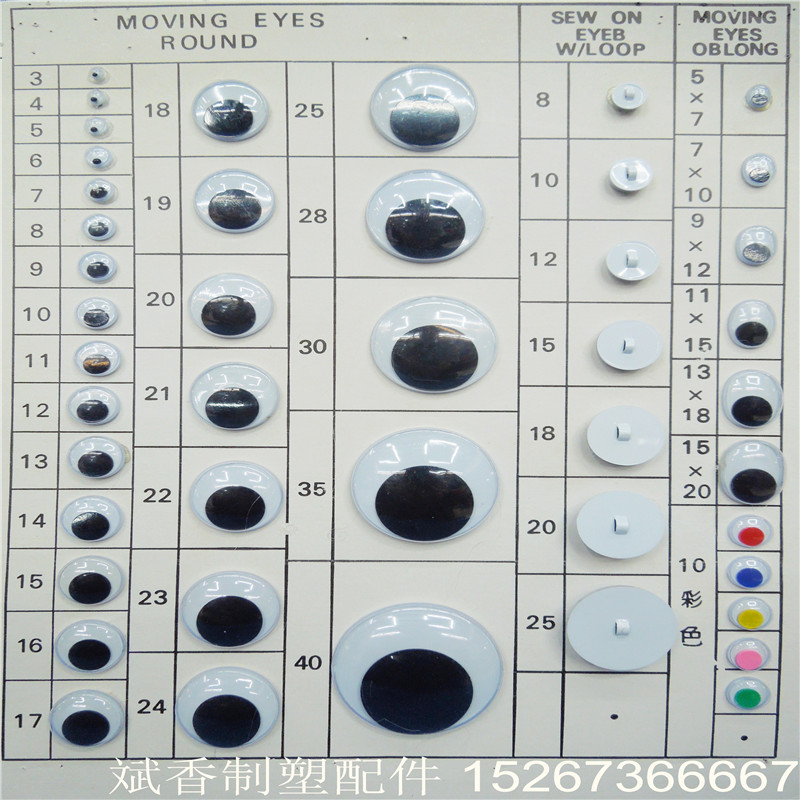

An eye tells a story. A Japanese resin eye might shimmer with delicate holographic flecks, designed for kawaii-style characters. Hand-blown Czech glass eyes offer unmatched refraction, mimicking real pupil dilation under light. Meanwhile, precision-molded Italian acrylics deliver bold colors ideal for fantasy creatures.

These aren’t merely aesthetic differences—they reflect generations of regional expertise. Compare them to mass-produced domestic imitations, and the contrast becomes clear. Imported eyes maintain their luster after years, resist chipping, and feature microscopic detailing around the iris rim that cheaper versions simply can’t replicate.

Behind every shipment lies a meticulous quality ritual. Before any container leaves the factory, each batch undergoes optical clarity tests, stress checks for movement mechanisms, and even simulated sunlight exposure. Think of it as curating a gallery of tiny masterpieces—because when your creation stares back at you, only perfection will do.

More Than Just Eyes: How Toy Accessories Speak Character

A button nose whispers vintage charm. Magnetic joints suggest hidden mobility. Faux-fur ears twitch with personality. These small elements are more than add-ons—they’re narrative tools. One Berlin-based designer uses hand-painted metal claws to signal a creature’s mythical origin; another Seattle artist combines glow-in-the-dark pupils with leather wings to evoke post-apocalyptic folklore.

We call this “accessories as language.” The shape of a brow bar, the texture of a tail connector—each choice communicates backstory without words. And when those pieces come from expert manufacturers who understand material science and longevity, they elevate playfulness into artistry.

From Sketch to Shelf: Your Design, Built on Their Production Line

Imagine sketching a dream eye: bi-color ombre, cat-shaped, with a subtle starburst pattern visible only in sunlight. With direct manufacturer access, that idea doesn’t stay on paper. Our process begins with your inspiration board—a mood collage, color codes, rough drawings. From there, digital mockups evolve into physical prototypes. We test UV resistance, check hinge mechanics, verify pigment stability.

And yes—you can start small. Whether you're launching a limited-run collection or testing a new brand concept, low minimum order quantities mean you don’t need to gamble on thousands of units. This flexibility empowers emerging labels and indie makers alike, turning experimental ideas into tangible products without financial risk.

The Power of the Sample: Why Smart Creators Test Before They Invest

Why do leading toy startups always request samples first? Because touch reveals truth. A photo can’t convey how a joint rotates smoothly after 10,000 bends, or how velvet-soft ear lining feels against skin. That’s why we offer complimentary sample kits—not just to impress, but to build trust.

Innovative creators use these samples in unexpected ways: embedding them in crowdfunding campaign boxes, mailing them to influencers for unboxing videos, or hosting “design lab” events where customers mix and match parts. Beyond marketing, sampling lets you evaluate responsiveness—how fast does the team revise a prototype? Do they anticipate issues you haven’t spotted?

It’s due diligence disguised as discovery.

The Sewing Table Revolution: DIY Communities Meet Global Sourcing

Scroll through Instagram hashtags like ArtDollCommunity or HandmadeToys, and you’ll see a surge of creators proudly showcasing dolls with striking imported eyes and articulated limbs. What fuels this trend? Transparent supply chains and user-friendly packaging. Multilingual instruction cards, QR-linked care guides, and standardized labeling make international components accessible—even for non-English speakers.

As barriers fall, micro-brands flourish. Artists who once sold locally now ship globally, supported by reliable component sources. We’re witnessing a democratization of design: anyone with a needle, a vision, and access to premium parts can build a signature style.

The Future Stares Back: Smart Eyes and Sensory Surfaces

What happens when accessories gain awareness? Emerging technologies hint at self-blinking eyelids activated by motion sensors, or thermochromatic irises that shift hue with room temperature. AR-enabled tags embedded in ears or bases allow digital storytelling overlays via smartphone apps—blending tactile joy with interactive narratives.

Soon, the line between object and experience may blur. When a doll’s eyes respond to its environment, what does that mean for the creator? Perhaps our role shifts from sole author to collaborative director—curating behaviors, designing reactions, orchestrating emotional arcs through programmable parts.

The future of toy making isn’t just handmade. It’s intelligent, intimate, and infinitely customizable. And it starts with a single decision: to go straight to the source.