Imagine a world where every doll, plush toy, or handmade creature you create doesn’t just look alive—but truly feels it. The secret? It’s in the eyes. At the heart of unforgettable toy design lies a tiny yet transformative detail: the activity eye. And when you source directly from manufacturers, you’re not just buying components—you’re unlocking a global standard of craftsmanship, customization, and cost efficiency.

From Factory to Creative Studio: The Journey Behind Every Imported Activity Eye

The finest activity eyes begin their journey in specialized manufacturing hubs known for precision tooling and advanced polymer engineering. These facilities blend decades of artisanal knowledge with cutting-edge automation, ensuring each eye moves smoothly, reflects light naturally, and withstands repeated interaction. By sourcing directly from these factories, designers bypass multiple middlemen—slashing lead times and reducing costs without compromising quality. This direct-to-creator model empowers both indie crafters and large brands to access import-grade materials at competitive rates, all while maintaining full control over timelines and specifications.

Eyes That Speak: Why Detail Defines Emotional Connection

A toy’s eyes are its first language. Before a single word is spoken or stitch is admired, a child—or collector—forms an emotional bond based on what they see in those glimmering orbs. An upturned iris suggests curiosity; a softly shaded pupil evokes innocence. With activity mechanisms like blinking or gentle rotation, toys gain lifelike expressiveness that transforms static figures into companions. Whether it’s a sleepy-eyed bear or an alert fantasy guardian, the right eye movement deepens engagement, making play more immersive and display pieces more captivating.

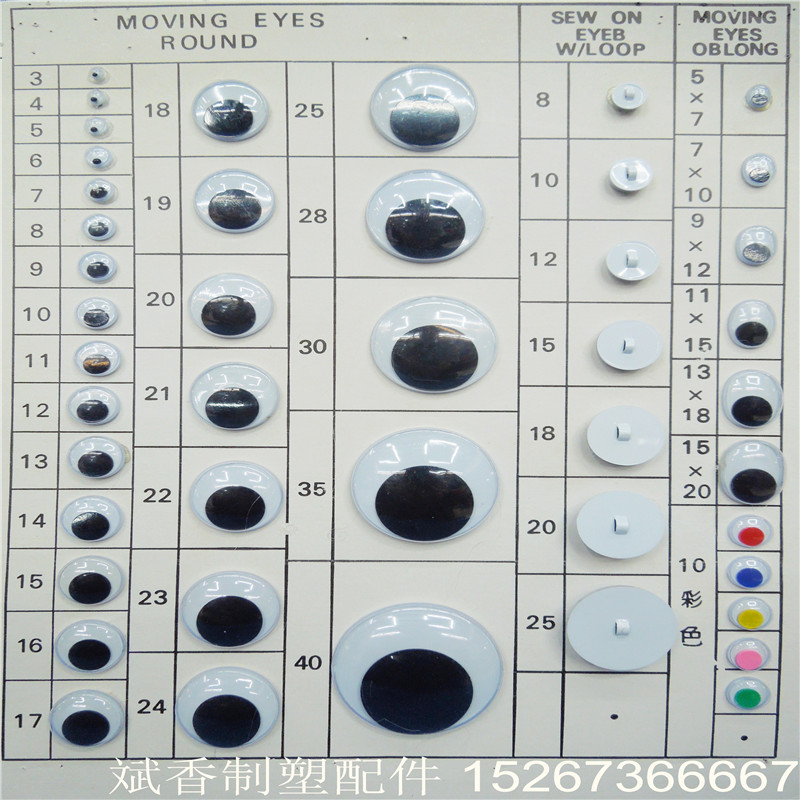

Design Your Gaze: Personalize Every Aspect of Your Activity Eye

Why settle for generic when you can define every detail? Our manufacturer-direct program opens the door to full customization—from diameter and curvature to intricate虹膜 (iris) textures and gradient color blends. Choose warm hazel tones for a vintage doll series, or metallic silver swirls for sci-fi action figures. Even the back-end installation method can be tailored: snap-in, screw-mount, or adhesive-ready designs ensure seamless integration across materials like fabric, resin, or vinyl. Real-world creators have used this flexibility to craft everything from wide-eyed toddler toys to hyper-realistic artist collectibles—all bearing a signature gaze that tells their story.

Built to Last: Inside the Durability Lab of Premium Activity Eyes

Not all eyes are made equal. While basic models may yellow under sunlight or crack after rough handling, high-performance activity eyes are engineered with resilience in mind. We rigorously compare materials such as ABS, PVC, and optical-grade resins for UV resistance, impact strength, and long-term clarity. Sealed dual-layer construction prevents internal fogging or dust infiltration, preserving smooth motion and crystal-clear vision—even after years of use. Independent testing confirms these eyes endure drop tests, friction cycles, and prolonged sun exposure far beyond industry standards—making them ideal for heirloom-quality creations.

The Power of a Sample: Smarter Design Starts with Testing

One sample can save hundreds of production hours. A renowned doll designer once discovered—only after receiving prototypes—that her chosen eye size caused tension in the eyelid fabric, leading to premature wear. Thanks to early sampling, she adjusted the diameter before mass production, avoiding costly rework. This is why we encourage all clients, whether solo artisans or corporate buyers, to request physical samples first. Seeing how the eye fits, moves, and reflects in real conditions reveals insights no CAD file can match. Small-batch trials reduce risk, refine fit, and accelerate time-to-market.

Favored by Makers and Brands Alike: Who Chooses Direct-Sourced Activity Eyes?

From Etsy-based sculptors to multinational toy corporations, one truth unites diverse creators: the need for reliable, customizable components. Independent artists value the freedom to experiment with unique designs without MOQ constraints. Meanwhile, established brands appreciate consistent quality, traceable sourcing, and scalable output—all available through the same supply chain. This duality speaks to the product line’s versatility: flexible enough for one-off projects, robust enough for industrial deployment.

Five Key Questions to Shape Your Perfect Eye Design

Before diving into customization, consider these essential factors: Who is your end user? Is this a baby-safe plush or an adult collector figure? What environment will it live in—indoors, outdoors, frequently handled? Do you want passive eyes or dynamic motion features? How will it be mounted on the material? And finally, what emotion should it convey? Answering these guides smarter decisions on size, finish, safety compliance, and mechanics—ensuring your final product aligns perfectly with intent.

Bringing Vision to Life: From Sketch to Physical Reality

We know inspiration strikes fast—but turning a sketched “spark” into a functional eye takes collaboration. Our technical team works closely with clients to interpret hand-drawn concepts, translate them into 3D renderings, and develop precise molds for prototyping. Complex textures, asymmetrical shapes, or integrated LED elements? We support ambitious ideas with engineering expertise. This partnership ensures your creative vision isn't limited by production feasibility—but elevated by it.

When you buy directly from the manufacturer, you're not just acquiring parts. You're gaining a partner in innovation—one that turns the quiet power of a glance into the soul of your creation.